Hayden also offers fully compliant api 661 air cooled heat exchangers with spiral wrapped fins with twisted tape turbulators and matrix turbulators to meet the most rigorous specifications in the industry.

Gas turbine lube oil cooler.

Our team of experts will travel anywhere in the world to clean your turbine s lube hydraulic or fuel oil.

Lube oil cooling systems.

However their waste energy is split between the exhaust lube oil system and jacket cooling system.

Turbine lubricants must control the rust and corrosion that could destroy precision surfaces resist foaming and air entrainment which could impair.

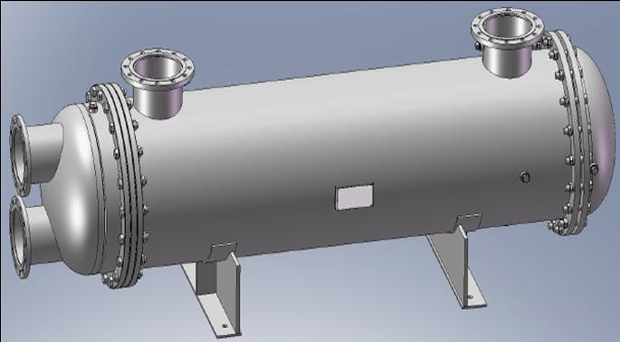

Coolers are utilized on lubricating oil reservoirs of large rotating equipment to control viscosity and reject heat.

To control the inlet chilling system ge will provide a modular hardware style plc.

Approximately 48 of the waste heat is in the exhaust stream 27 removed by the lube oil system and 25 removed by the jacket cooling system.

Reciprocating engines like gas turbines run at efficiencies near 30.

Lube oil cooler performance is impacted by a number of plant specific variables.

The importance of the turbine lube oil cooler is maintaining optimum oil temp of the turbine lube oil and if this exchanger experiences leaks it can result in contamination of the lube oil or release of turbine lube oil into the environment.

Efficient turbine lube oil cooling is critical to the reliability of turbine generator or turbine driven compressor applications.

Gas turbine combined lube and control oil in gas turbine power plants lubrication of the bearings on the turbine shaft main roller journal thrust bearings keeps the turbine running at its optimum.

Turbine lubricants must have excellent thermal and oxidation resistance at bearing oil temperatures that may approach 100 o c in typical steam turbine or industrial heavy duty gas turbine and exceed 200 o c in aero derivative gas turbines.

Some units may have the evaporative cooler pre installed while others will require the filter house to be opened.

The lubrication system usually consists of a large storage tank coolers to remove heat from the oil and pumps to circulate the oil.

A drift eliminator to limit water entering the turbine.